High-Speed

Machining

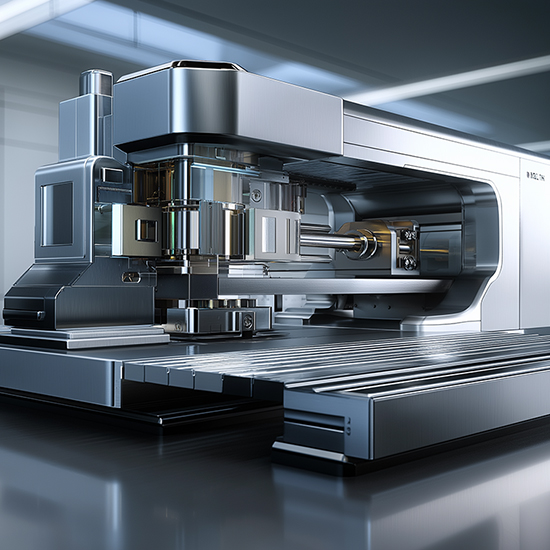

JINYOUNG TBX High-Speed Machining (HSM) applies optimized cutting strategies, tooling and machine control to remove material faster while protecting part quality. We support turbine blades, blisks, impellers and precision parts that demand stable surface integrity, tight tolerances and shorter cycle times in power, aerospace and industrial applications.

JINYOUNG TBX high-speed machining cells combine rigid spindles, high-RPM tooling, optimized toolpaths and real-time control. We focus on reducing cycle time and improving surface quality for critical turbomachinery and aerospace components without compromising dimensional accuracy or tool life.

Speed with

Control & Quality.

High-Speed Roughing Strategies.

Dynamic toolpaths and constant-chip-load cutting remove material efficiently while keeping spindle load, vibration and heat under control ??ideal for blade root pockets, deep cavities and complex 3D shapes.

Surface Integrity & Dimensional Control.

High-speed finishing passes, small step-over and proper coolant / lubrication deliver low roughness and stable edge quality, while CMM verification ensures that tolerances remain within design limits.

Productivity & Process Integration.

High-speed machining is integrated with CAD / CAM, tooling libraries and quality plans so that process windows are defined, documented and repeatable from prototype to mass production and repair work.

High-Speed Roughing & Semi-Finishing

High-Speed Finishing & Polishing

HSM Tooling & Process Optimization

Quality & OEM System Alignment

A high-speed machining workflow

tuned for quality, cost and lead time.

The JINYOUNG TBX High-Speed Machining team works closely with engineering and quality to define safe cutting windows, select suitable tools and holders, and design fixtures that support stable, repeatable processes at elevated spindle speeds and feed rates.

Whether the goal is to shorten delivery for new parts, reduce cost for serial production or improve the surface and fatigue performance of critical components, we balance spindle utilization, tool life and inspection results to deliver predictable, production-ready machining solutions for our customers??most demanding parts.