CAD / CAM / CAE

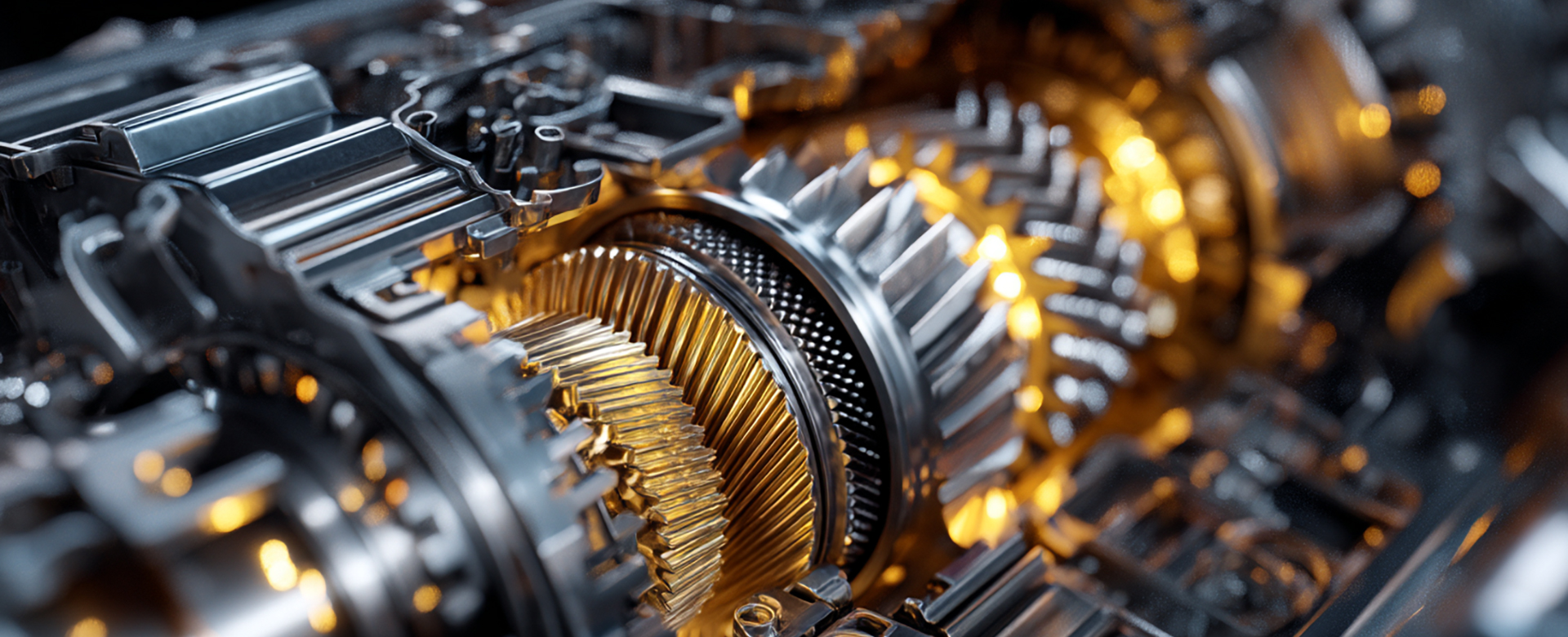

JINYOUNG TBX integrates CAD, CAM and CAE to support the full digital engineering cycle for turbine blades, vanes, rotors and precision parts. From 3D design and parametric modeling to toolpath generation and structural / flow analysis, we connect virtual development with manufacturing and quality for reliable, data-driven production.

JINYOUNG TBX uses integrated CAD / CAM / CAE platforms to design complex turbomachinery components, generate optimized machining programs and validate performance virtually. This digital thread shortens development time, reduces risk and supports consistent quality from prototype through mass production.

One Digital Flow

from Design to Shop Floor.

CAD: 3D Design & Digital Twin.

Creation of detailed 3D models for blades, vanes, rotors and housings, with parametric features, design rules and assemblies that capture geometry, clearances and interfaces for downstream use.

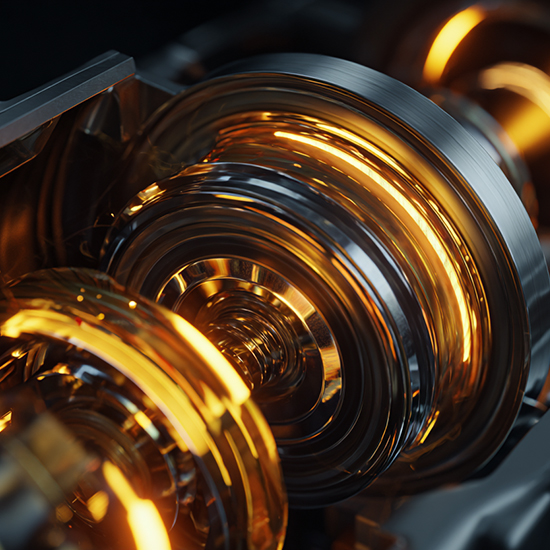

CAM: Toolpath & Process Planning.

Generation of optimized 3-axis and 5-axis toolpaths, cutting parameters and machining strategies that balance surface quality, tool life and cycle time across prototypes, series parts and repair work.

CAE: Virtual Analysis & Validation.

Use of structural, thermal and flow analysis to check stress, deflection, cooling and performance before manufacturing ??supporting design optimization and reducing the risk of trial-and-error on hardware.

3D Modeling & Digital Twin

CAE Analysis & Optimization

A CAD / CAM / CAE workflow

that links design, machining and quality.

The JINYOUNG TBX CAD / CAM / CAE team works alongside R&D, manufacturing and quality to keep a single source of truth for geometry and process data. From initial concept to shop-floor NC code and inspection programs, we maintain traceability and consistency across all stages.

Whether the objective is a new blade design, a cost-optimized machining process or a simulation-driven redesign, we ensure that models, toolpaths and analysis results are aligned and documented, so that our customers receive parts that behave as expected in both virtual and real operating environments.