5-Axis

Machining

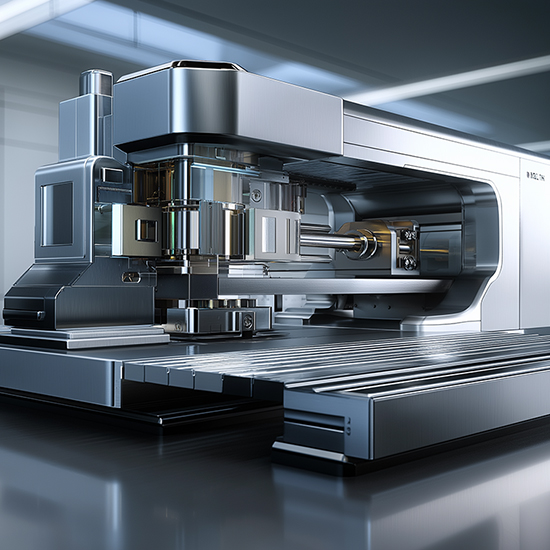

JINYOUNG TBX 5-axis machining enables complex turbine blades, blisks, impellers and precision parts to be produced in fewer setups with higher accuracy. By synchronizing tool and table motion across five axes, we achieve stable surface quality, tight tolerances and efficient production for challenging geometries in power generation, aerospace and industrial applications.

JINYOUNG TBX 5-axis machining centers are configured for turbomachinery and aerospace work, combining high rigidity, rotary tables and advanced control systems. We handle everything from prototype development to serial production of complex curved surfaces.

Precision

from Every Angle.

Complex Curved Geometry.

Simultaneous 5-axis machining of twisted airfoils, free-form surfaces and deep undercuts for turbine blades, blisks, impellers and housings with reduced setup count and higher accuracy.

Accuracy, Surface & Tool Life.

Optimized toolpaths, cutting parameters and fixturing deliver consistent profiles, low chatter and good surface finish, while protecting tools and machines during high-speed 5-axis machining.

Integrated with CAD / CAM & Quality.

5-axis programs are developed in close link with CAD / CAM models and inspection plans, ensuring that machined parts match design data and can be efficiently verified and documented for OEM and customer requirements.

CAD / CAM Integration & Simulation

Quality & OEM System Alignment

A production-proven 5-axis workflow

from digital model to finished component.

The JINYOUNG TBX 5-axis team integrates CAD / CAM engineers, machine operators and quality specialists. We start from validated 3D models, develop collision-checked toolpaths, select tools and fixtures, and verify results with CMM and functional checks.

Whether the objective is new product introduction, cycle-time reduction or quality improvement, we focus on stable, repeatable machining processes that fit into our customers’ engineering and OEM requirements – from prototype to mass production and repair work alike.