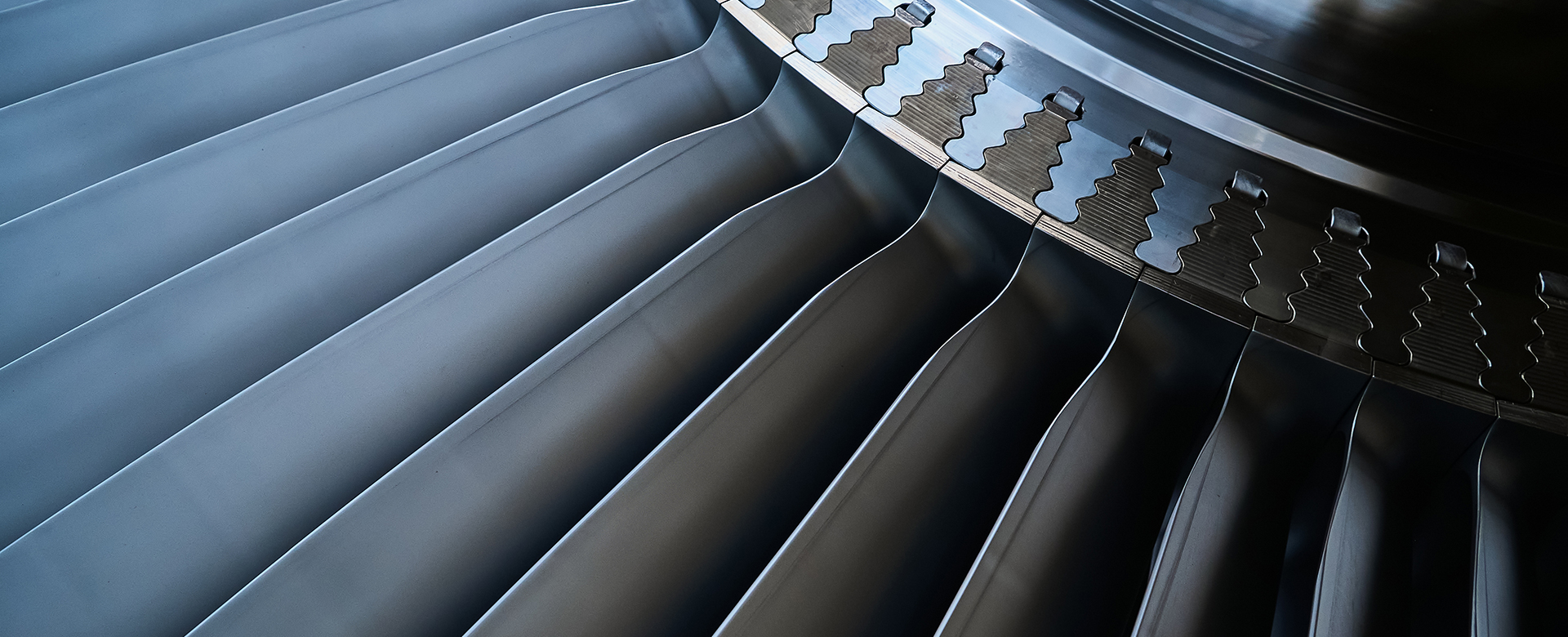

QC & Compliance

JINYOUNG TBX builds quality and compliance into every step of the manufacturing process. From material approval and in-process control to final inspection and certification, our QC and compliance systems ensure that turbine blades, vanes, rotors and precision parts meet global standards and OEM requirements for safety, reliability and traceability.

Controlled Processes,

Proven Compliance.

Our QC & compliance framework covers the full value chain '' incoming inspection, in-process control, special process validation and final release ''supported by documented procedures, trained inspectors and traceable records aligned with international standards and OEM systems.

Quality Planning

& Standards

Translation of customer and OEM specifications into control plans, inspection requirements and work instructions for each product family and operation.

In-Process Control

& Monitoring

First-piece approval, patrol inspection, SPC and tool / machine monitoring to keep critical dimensions, surfaces and tolerances within target windows.

Final Inspection

& Testing

CMM / airfoil measurement, functional checks, visual inspection and, where required, NDT and performance tests prior to product release.

Compliance,

Documentation & Audit

Preparation and retention of certificates, inspection reports and traceability records to support customer audits, regulatory reviews and OEM approvals.

QC & Compliance

Our QC & compliance system combines international quality standards with customer-specific requirements. Procedures cover incoming inspection, process control, special processes, calibration, nonconformance management and corrective action. Regular internal audits and KPI reviews help us maintain and improve safety, quality, cost and delivery performance.

For safety-critical turbine and rotating components, we provide full traceability from raw material to finished part. Inspection records, CMM data, heat treatment and coating certificates and release documentation are securely stored and made available for OEM review, customer audits and long-term fleet support. This disciplined approach enables our customers to rely on JINYOUNG TBX as a compliant, transparent manufacturing partner.

Key QC & Compliance Practices

-

Structured Quality System ''/b> Documented procedures for contract review, process planning, production, inspection, calibration, NCR and corrective action, aligned with global quality standards.

-

In-Process & Final Inspection ''/b> Defined inspection points, CMM / airfoil measurement, gauge checks and visual inspection to verify all critical features before release to the next stage or shipment.

-

Special Process Control ''/b> Qualified heat treatment, coating, welding, shot peening and other special processes controlled by written procedures, approvals and periodic re-qualification.

-

Traceability & Record Management ''/b> Unique identification of materials and parts, linked to process data, inspection results and certificates for full backward and forward traceability.

-

Audit & Continuous Improvement ''/b> Internal audits, customer and OEM assessments, and structured improvement activities that feed lessons learned back into standards, training and daily operations.