CMM

Inspection

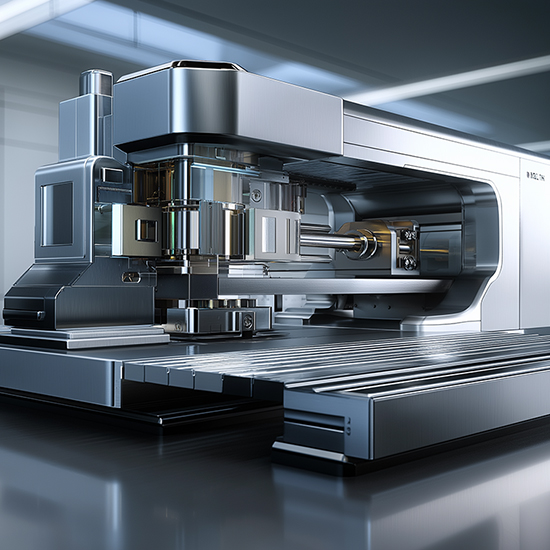

JINYOUNG TBX uses coordinate measuring machines (CMMs) to verify the geometry of turbine blades, vanes, rotors and precision parts with micron-level accuracy. By combining probing and scanning, automated inspection programs and strict environmental control, we support stable, traceable quality for power generation, aerospace and industrial turbomachinery components.

JINYOUNG TBX CMMs are configured for turbomachinery and aerospace parts, with touch-trigger and scanning probes, rotary tables and dedicated inspection software. We measure complex airfoils, roots, platforms and bores under controlled conditions to ensure that every part matches design intent and OEM requirements.

Precision Data

for Critical Parts.

Full 3D Coverage & Accuracy.

Multi-axis probing and scanning measure profiles, thickness, run-out, twist and alignment over complex shapes such as turbine blades, blisks, impellers and rotors, ensuring they remain within tight tolerances.

Automated Programs & Reporting.

Standardized CMM programs, automated alignment, batch inspection and report templates support repeatable measurement and fast feedback to production, engineering and customers.

Environment, Calibration & Traceability.

Controlled temperature and humidity, regular calibration, gauge blocks and traceable reference parts ensure that CMM results remain stable over time and are fully documented for audits and OEM quality systems.

Rotor, Disc & Hub Measurement

Impeller, Pump & Compressor Parts

A CMM inspection workflow

that links design, machining and quality.

The JINYOUNG TBX CMM team works from approved drawings and 3D models, builds clear inspection plans and programs, and coordinates with machining and R&D to focus on the features that matter most for performance and safety. Measurement results are stored and reported in formats that support OEM and customer quality systems.

Whether the goal is initial sample inspection, capability studies, routine production checks or troubleshooting field issues, we use CMM data to provide objective evidence of part quality and to drive continuous improvement in our manufacturing and design processes.