Featured Global Project

- Category : Gas / Steam Turbine Blade Supply

- End User : Major Power Utility (Overseas)

- Industry : Power Generation & Industrial Energy

- Project Period : 2021 ''2028 (Phased Delivery)

Project Overview

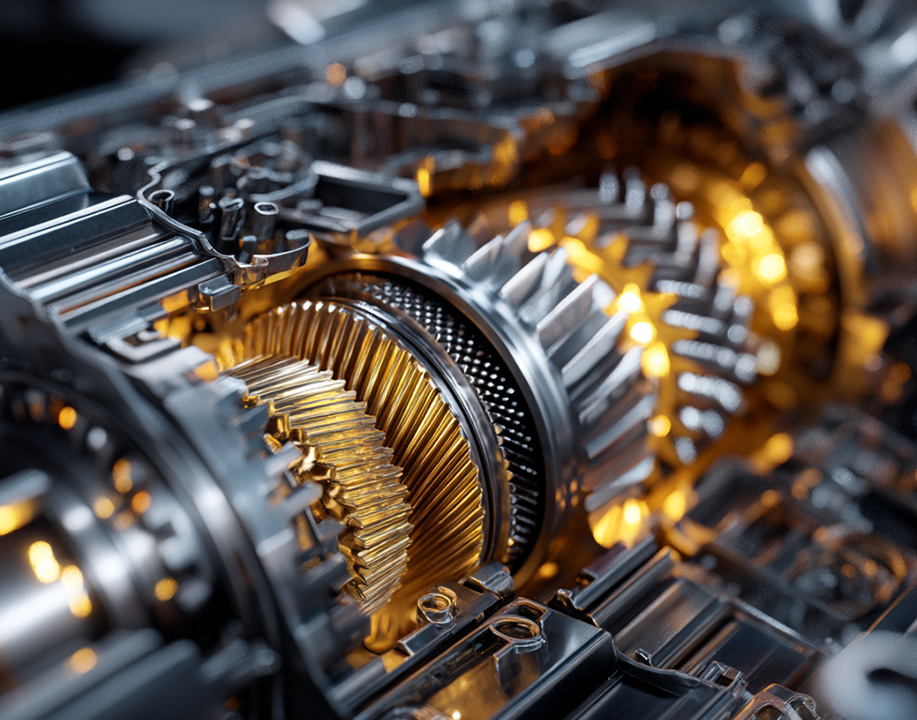

JINYOUNG TBX supplied turbine blades, vanes and associated hot-gas-path components for a series of large combined-cycle and steam power plants located in Asia and the Middle East. The project required high-efficiency blade designs, strict quality control and a phased delivery plan aligned with unit outages and new-build schedules.

Working in close cooperation with global OEMs and EPC contractors, we supported the full lifecycle of the project ''from design review and prototype validation through serial manufacturing, site integration and long-term spare parts supply. Our role was to ensure that every blade set met performance, durability and schedule targets, contributing to safe and reliable operation of the global power fleet.

Turbine Blade Supply Scope

The project involved the design and manufacture of gas turbine first-stage and downstream blades, steam turbine IP/LP blades, guide vanes and associated hot-gas-path components. JINYOUNG TBX applied proven airfoil designs, advanced materials and precision machining processes to deliver blade rows optimized for efficiency, reliability and ease of maintenance.

Our Project Approach

-

Engineering Collaboration ''/b> Joint review of blade profiles, cooling schemes, materials and quality plans with OEM and EPC partners to align design intent and manufacturability.

-

Integrated Manufacturing ''/b> Use of 5-axis machining, high-speed milling, heat treatment, coating and CMM inspection in a single facility to shorten lead time and secure consistent quality.

-

Phased Delivery & Logistics ''/b> Production and shipping schedules synchronized with plant outage windows, installation sequences and site storage constraints.

-

Lifecycle Support ''/b> Provision of spare blade sets, repair / recoating options and technical support to help customers manage long-term performance and risk.

Project Challenges & Solutions

The global project portfolio included new-build and retrofit units with different turbine models, operating conditions and local regulations. To respond, JINYOUNG TBX established project-specific teams that managed design variants, materials and documentation in close cooperation with each customer.

By standardizing core manufacturing processes and adapting fixtures, programs and inspection routines to each turbine type, we were able to deliver multiple blade families in parallel while maintaining common quality and traceability standards. This approach reduced overall project risk and helped our partners keep to tight construction and outage schedules.