Aerospace Components

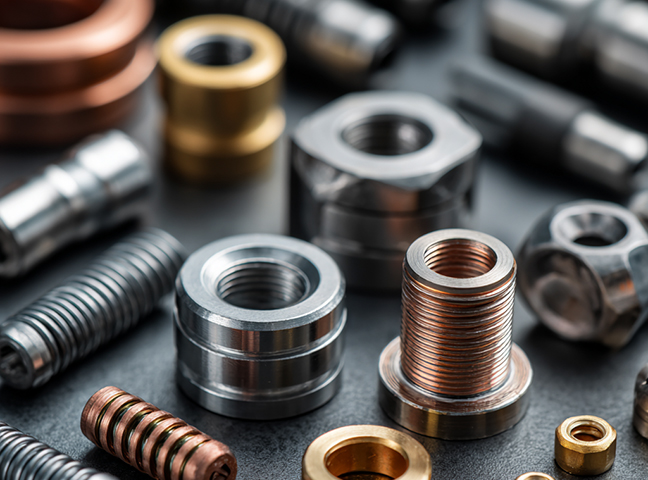

JINYOUNG TBX supplies precision aerospace components for turbine engines and airframe systems. From rotating hot-section hardware to structural and mounting parts, our components are engineered to meet strict aerospace requirements for strength, weight, reliability and traceability in flight and ground test environments.

Products

Selected Aerospace Component Projects (1982''026)We provide machined and fabricated aerospace components that support safe, efficient and dependable operation of propulsion and airframe systems in commercial and defense platforms.

Jinyoung TBX

Product Advantages

Aerospace-Grade Quality & Traceability

Our aerospace components are manufactured under controlled processes with full material traceability, documentation and inspection records to meet global aerospace and engine OEM standards.

Lightweight, Durable Design

Using aerospace alloys and optimized geometries, we help reduce component weight while maintaining the stiffness, fatigue strength and thermal resistance required in engine and airframe systems.

Engineering Collaboration & Lifecycle Support

We work with engine and airframe designers from prototype through serial production and MRO, supporting design-for-manufacture, cost-effective machining strategies and repair / replacement concepts over the entire lifecycle.