Industrial Driving

JINYOUNG TBX supports industrial drive systems that power production lines, material handling, fans, pumps and compressors. From turbine-driven trains to motor-gearbox assemblies and couplings, our precision components help customers achieve stable, efficient and reliable transmission of power in demanding industrial environments.

Service Overview

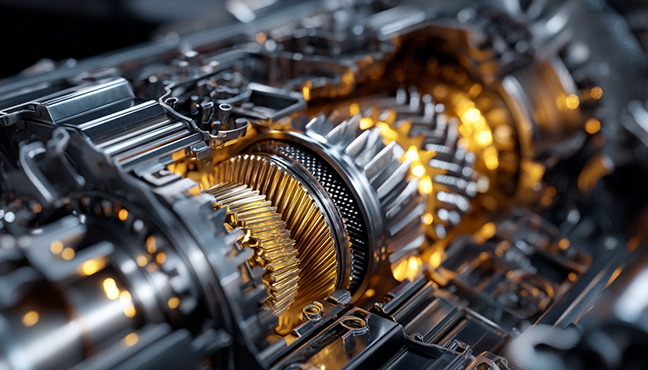

Industrial drive systems transfer mechanical power from turbines, motors or engines to driven equipment such as conveyors, blowers, pumps and mixers. JINYOUNG TBX manufactures key rotating parts for these systems ''including shafts, couplings, gears, rotors and high-precision housings ''that must operate under continuous load, frequent starts and varying torque demands.

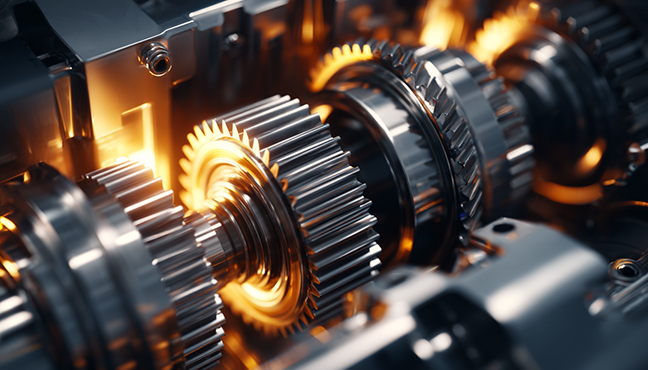

By combining robust materials, precision machining and careful dynamic balancing, we help OEMs and plant operators reduce vibration, extend bearing and gear life, and maintain stable output, even in heavy-duty environments such as steel, petrochemical, power generation and general manufacturing plants.

Our Role in Industrial Drive Systems

-

Drive Trains & Gear Units ''/b> Shafts, gears, pinions and rotor parts for motor-driven and turbine-driven gearboxes used in fans, compressors, pumps and conveyors.

-

Couplings & Power Transmission ''/b> Precision components that connect prime movers to driven equipment, helping control torsional vibration and misalignment in rotating trains.

-

New Manufacture & Replacement ''/b> OEM-compatible and reverse-engineered components for new projects, modernization and performance restoration of existing drive systems.

-

Lifecycle & Reliability Support ''/b> Dimensional inspection, reconditioning and balancing services that keep industrial drives within design clearances and availability targets.

What We Offer

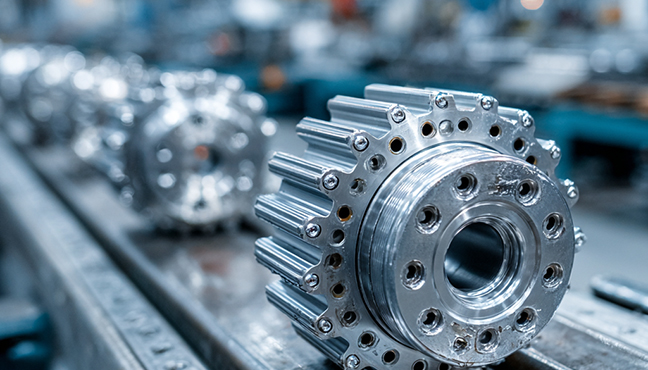

Drive Shafts, Gears & Housings

- + Shafts, gears, pinions and keyed/FIT interfaces

- + Housings and bearing seats with tight tolerances

- + Designs for high torque and continuous-duty service

Couplings, Interfaces & Alignment

- + Rigid and flexible coupling-related precision parts

- + Interfaces designed for smooth torque transfer

- + Support for accurate alignment and low vibration trains

Reliability, Efficiency & Fleet Support

- + Support for single drives and complex multi-train systems

- + Inspection, balancing and dimensional verification

- + Focus on uptime, energy savings and maintenance reduction