Manufacturing Process

JINYOUNG TBX applies a structured manufacturing process for turbine blades, vanes, rotors, impellers and precision-machined parts. From process planning and primary shaping through CNC machining, special processes and final inspection, every step is controlled to deliver stable quality and repeatable performance for power generation and aerospace customers.

From Planning to

Finished Components.

Our manufacturing process is divided into clear stages ''engineering, primary shaping, precision machining, special processes and inspection '' so that every part follows a consistent, traceable route from raw material to qualified product.

Engineering &

Process Planning

Review of drawings and 3D models, selection of materials, creation of process plans, tooling and inspection requirements before machining begins.

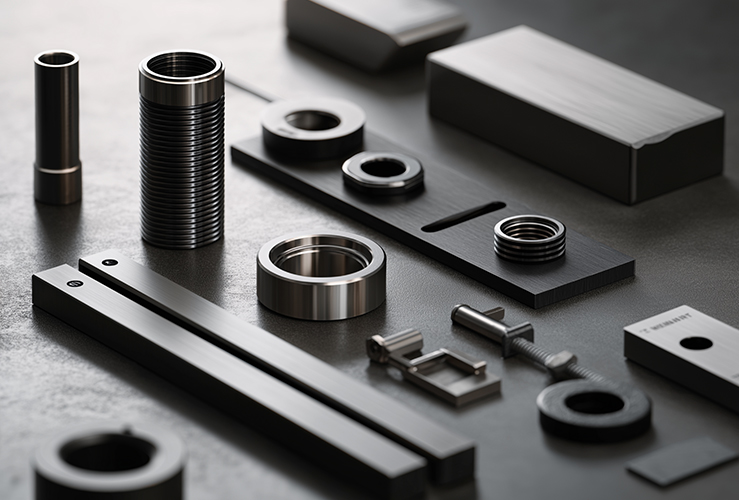

Material Prep &

Primary Shaping

Cutting, forging or casting of billets and preforms, followed by identification, pre-machining and stabilization to prepare for CNC operations.

Precision Machining

& Special Processes

3-axis / 5-axis and high-speed machining, heat treatment, coating, deburring and balancing to achieve final geometry and surface integrity.

Inspection,

Documentation & Shipping

CMM / airfoil inspection, visual checks, preservation, final review of certificates and packing before shipment to global OEM and end-user sites.

Manufacturing Process

Our manufacturing process is built around stable, repeatable operations for high-value rotating parts. Every new component begins with process planning, risk review and trial runs, so that production sequences are fully defined before long-term orders are released to the shop floor.

Throughout machining and special processes, in-process checks, SPC data and final inspections are linked to our quality & OEM systems. This allows us to maintain consistent dimensional control, validate heat treatment and coating performance, and provide the documentation our customers require for safety-critical equipment.

Key Process Steps

-

Process Planning & Tooling ''/b> Definition of routing, operations, fixtures, tools and inspection points based on customer drawings, 3D models and standards.

-

Primary Shaping ''/b> Forging, casting or bar stock cutting to create preforms with the required material properties and stock allowance for CNC machining.

-

Precision Machining ''/b> Roughing, semi-finishing and finishing on dedicated 3-axis / 5-axis and high-speed machining centers with controlled parameters and tooling.

-

Special Processes ''/b> Heat treatment, coating, shot peening, grinding and polishing in line with OEM specifications and qualified procedures.

-

Inspection & Release ''/b> CMM / airfoil measurement, functional checks, visual inspection and documentation review prior to packing and shipment.