Collaboration Program

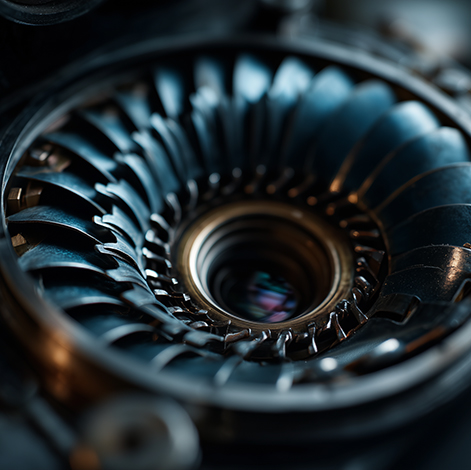

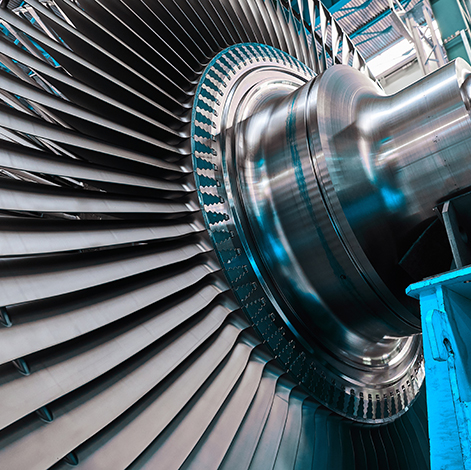

- Focus : Turbine Blade Co-Development & Lifecycle Support

- Partners : OEMs, Utilities, EPCs, Research Institutes

- Scope : Design, Manufacturing, Testing, Service

- Format : Joint R&D, Long-Term Supply & Service Programs

Program Overview

JINYOUNG TBX operates turbine blade collaboration programs that connect our design and manufacturing expertise with the operational experience of global partners. Through these programs, we jointly develop high-efficiency blades and hot-gas-path components, optimize existing fleets and create long-term support models that improve availability and reduce lifecycle cost.

In cooperation with OEMs, power producers and EPC contractors, we provide a structured framework for co-engineering, prototype validation, series production and field support. Our goal is to become a trusted extension of our partners''engineering and supply chain organizations, enabling them to respond quickly to new project demands and fleet improvement opportunities.

Turbine Blade Collaboration Scope

Our collaboration programs cover the full value chain of turbine blade and hot-gas-path components ''from front-end design studies and prototype manufacturing to fleet-wide upgrades and long-term service strategies. Partners can selectively join individual modules or build a multi-year program that reflects their project pipeline and fleet roadmap.

Collaboration Models

-

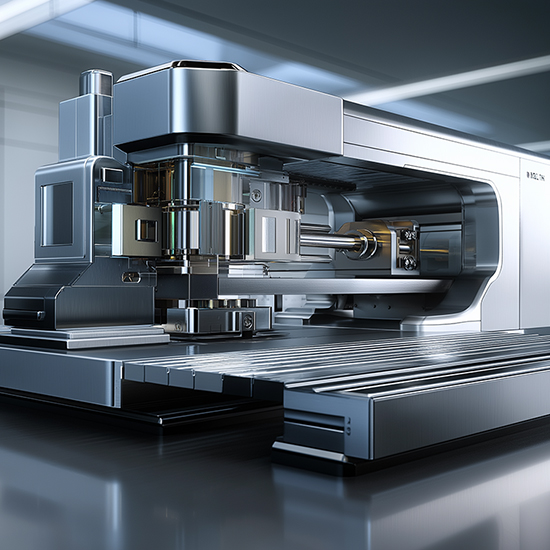

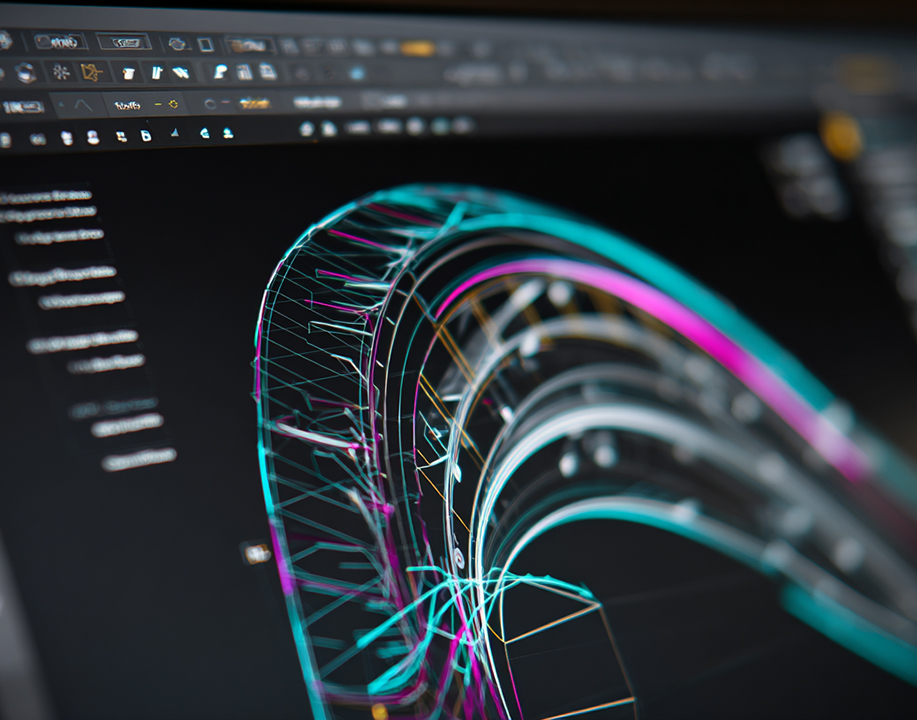

Co-Engineering Programs ''/b> Joint development of new turbine blades and vanes, including aero / thermo design support, manufacturability reviews and prototype validation in line with OEM standards.

-

Technology Transfer & Licensing ''/b> Structured programs that enable partners to leverage JINYOUNG TBX know-how, tooling and processes for localized manufacturing and service where required.

-

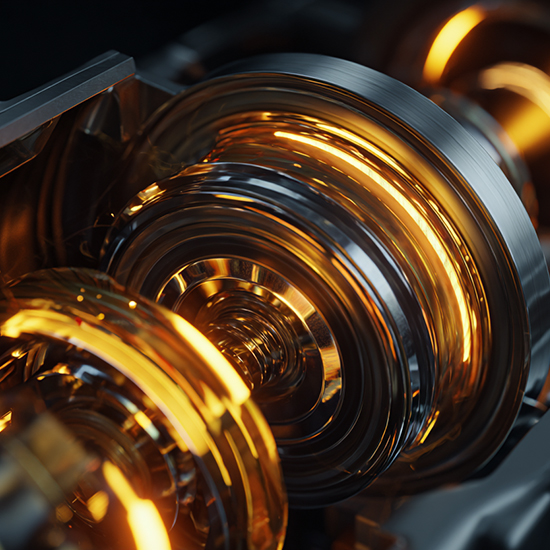

Fleet Upgrade & Retrofit Campaigns ''/b> Collaborative projects to improve output, efficiency and maintenance intervals of existing units through optimized blade designs, new materials and repair technologies.

-

Training & Engineering Support ''/b> Technical workshops, on-the-job training and digital support tools that help partner teams apply best practices in design, inspection and operation of turbine blades.

Partner Benefits & Outcomes

Collaboration programs are designed to reduce technical risk and shorten time-to-market for new blade solutions. By combining field feedback with our manufacturing and R&D capabilities, partners gain faster access to validated designs and industrialized production routes.

Typical outcomes include higher turbine efficiency, extended run-time between overhauls, more competitive lifecycle cost and improved flexibility in responding to market needs. In addition, shared data and joint lessons learned are fed back into future designs, creating a continuous improvement loop across the entire partner network.