JINYOUNG TBX announces enhanced turbine blade technology roadmap for next-generation gas & steam turbines

JINYOUNG TBX has unveiled its updated turbine blade technology roadmap, aligning with the global trend toward higher-efficiency, lower-emission gas and steam turbines. Building on Korea’s rapid progress in large gas turbine development and export, the company is strengthening its R&D and manufacturing capabilities to support hydrogen-ready and high-efficiency turbine platforms.

Recent industry announcements highlight record-breaking performance from new 380 MW-class gas turbines, extended 8,000+ hour demonstration runs and the first overseas exports of domestically developed turbine units. In this environment, high-reliability turbine blades and hot-gas-path components have become a key enabler for efficiency, flexibility and lifecycle cost reduction across global power fleets.

Key directions of the JINYOUNG TBX turbine blade roadmap

-

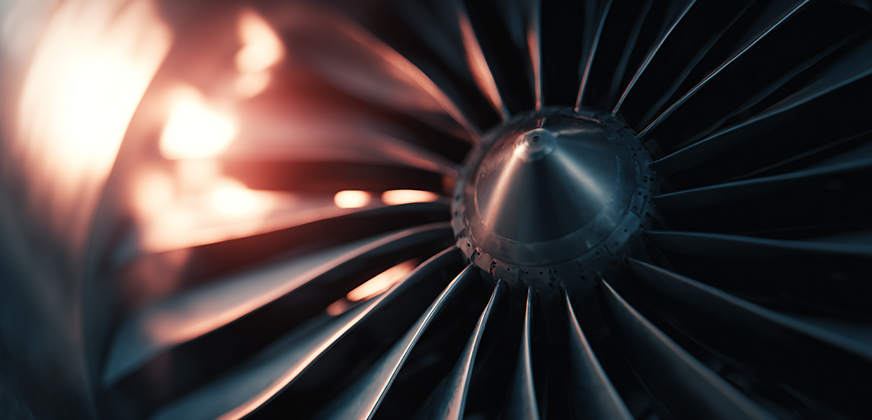

Higher efficiency & output – Development of advanced airfoil designs and optimized cooling architectures to support higher firing temperatures and improved combined-cycle efficiency.

-

Hydrogen-ready design – Material and coating strategies able to operate on natural gas today and gradually increase the share of hydrogen and low-carbon fuels in the future.

-

Enhanced lifecycle reliability – Blade platforms designed for longer maintenance intervals, improved erosion resistance and robust repairability to support long-term service agreements.

-

Digital quality assurance – Integration of CAD / CAM / CAE, CMM inspection and data-driven monitoring to ensure traceable, repeatable blade quality from prototype to mass production.

Collaboration with global OEMs and domestic partners

JINYOUNG TBX is expanding collaboration with OEMs and local partners in Korea’s turbine ecosystem to jointly develop and qualify new blade technologies. This includes cooperation on design validation, quality assessment and material research, as well as support for overseas projects where Korean turbine platforms are being introduced to new markets.

Through these programs, the company aims to become a core supplier for high-value turbine blades and hot-gas-path components, contributing to safer, more efficient and lower-carbon power generation around the world.

Focus on cooling, materials and serviceability

To support high-firing-temperature operation, the new blade roadmap emphasizes advanced internal cooling passages, film cooling concepts and optimized leading-edge protection. Combined with state-of-the-art coatings and high-strength alloys, these designs aim to deliver improved thermal margins without compromising structural integrity.

Serviceability is another core design principle. Cooling-hole layouts, attachment features and repair allowances are being engineered to facilitate inspection, refurbishment and life-extension work during outages, helping operators maximize asset value over the full life of the turbine.

Looking ahead

As global demand grows for cleaner, more flexible power generation, turbine blades will continue to play a decisive role in achieving higher efficiency and lower emissions. JINYOUNG TBX will keep investing in R&D, production technology and partnerships so that customers operating advanced gas and steam turbines can rely on a stable supply of world-class blade solutions.